Curved Cross-Laminated Timber

Barcelona, Spain | 2022Work performed during studies at Institute for Advanced Archicture of Catalonia in collaboration with İpek Attaroğlu, Jordi Vilanova, and Libish Murugesan | Faculty: Alexandre Dubor, Marielena Papandreou.

Leveraging the naturally occuring deformation in timber to create self-shaping curvature in cross-laminated timber (CLT) panels.

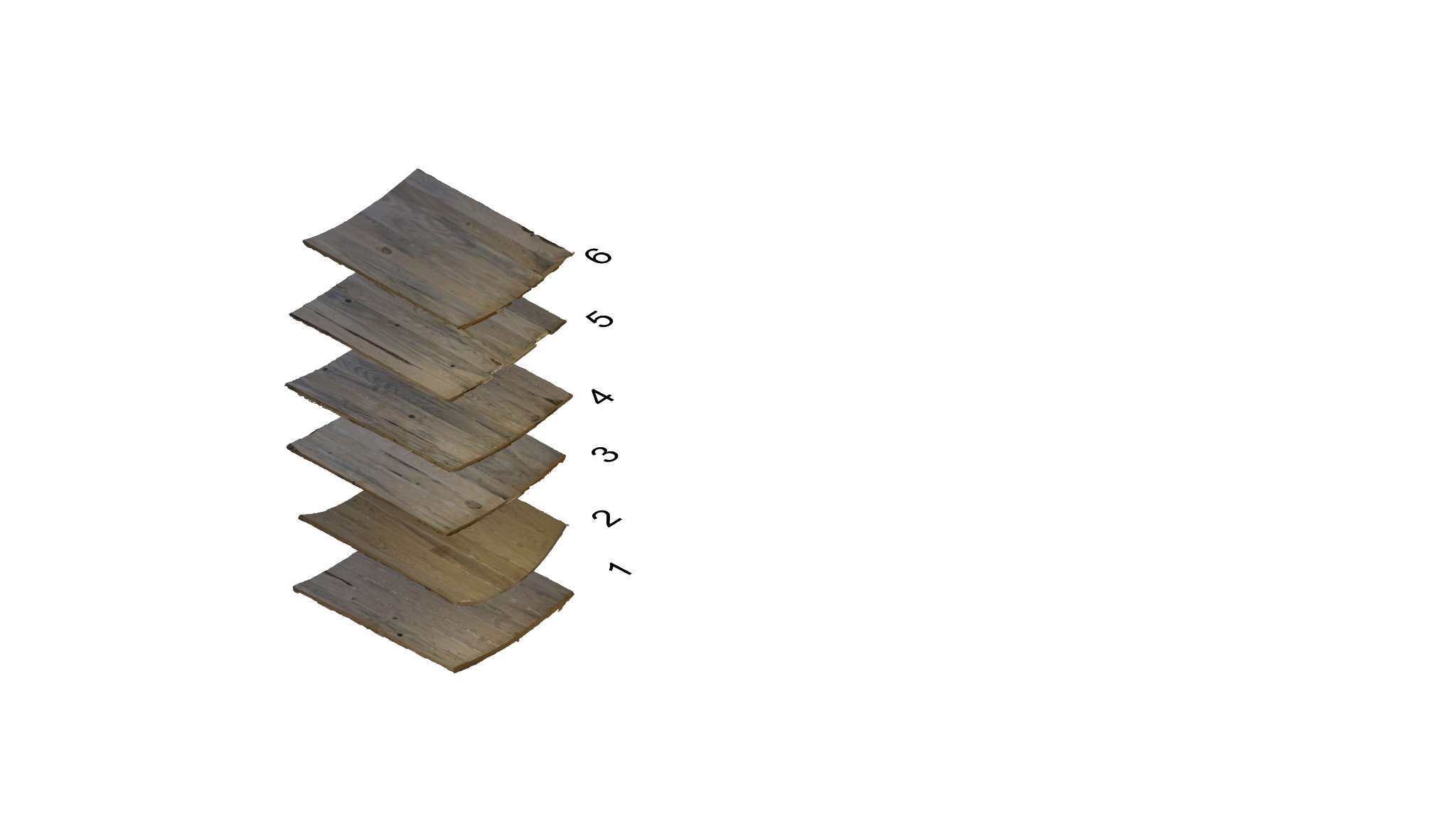

By taking advantage of the plain sawn offcuts - and thus consistent grain patterns, as well as the hygroscopic properties of the green (freshly cut) wood - which has a high moisture content - a subtle, yet consistent curvature known as cupping forms as the wood dries.

Offcuts salvaged from milling waste piles were selected based on grain pattern and viability as members within the panels. These were then processed, into straight pieces of consistent thicknesses allowing them to both fit neatly together during the pressing process and re-expose the fibers to the moisture in their environment.

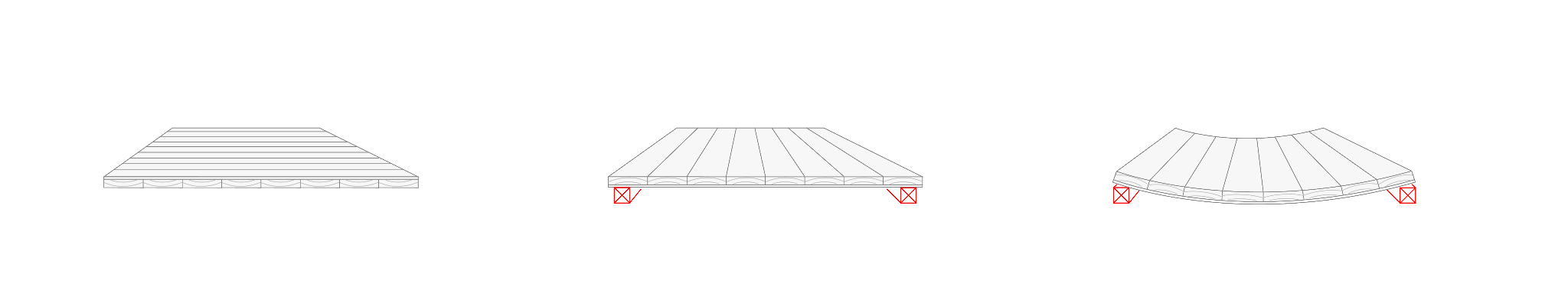

After being pressed and letting the glue cure overnight, the CLT panels were moved to a stable indoor environment and left to dry. Blocking was placed underneath the edges using gravity to aid in the deformation.

After processing the material, several studies were conducted on individual pieces to measure moisture content, environmental temperature and humidity, thicknesses, and the role these parameters played in informing a final curvature once the wood reaches a stable moisture level. Using these inputs, the project explored several methods to help model and predict this curvature, namely: machine learning, Timoshenko beam theory, and finite element analysis.

Through the observations resulting from these seasoning experiments, it was learned that a careful balance amongst these parameters had to be achieved to generate a substantial curvature without negatively impacting the wood's grain structure - especially checking, where stress in the wood results in cracks that occur perpendicular to the wood's growth rings - affecting not only the wood's structural integrity, but also work to straighten the pieces and lessening the curvature.

After two weeks of seasoning, the panels were milled into their final form using a 6-Axis Kuka KR150 mounted with a router.

To scan and calibrate the work pieces, several methods were explored - including photogrammetry, 3D mapping using the motion-controllers equipped with a VR headset, and ultimately using the robot arm itself to model the 3D geometry and generate the toolpaths.

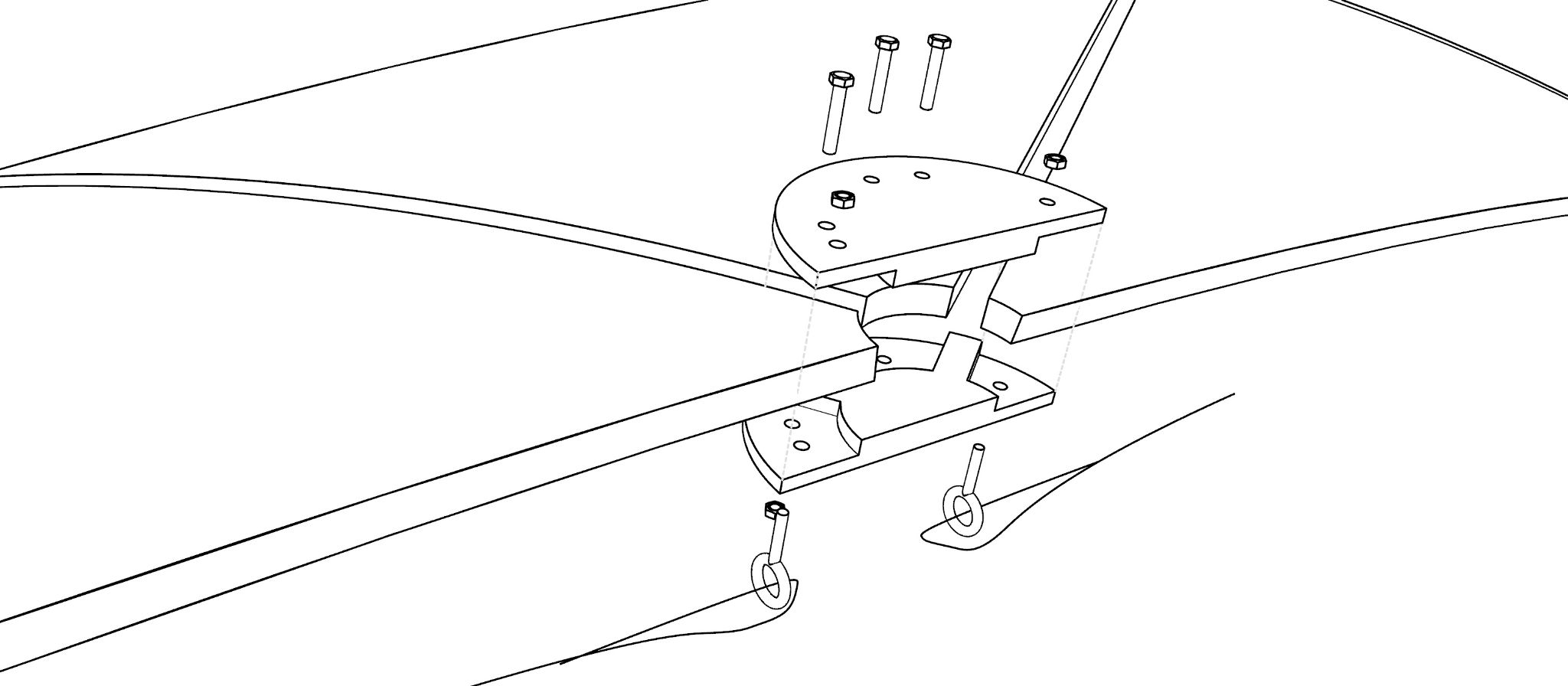

The prototype's helical design takes the form a developable strip - a geometry in which double-curvature is achieved through the manipulation of a flat object. The panels - which comprise a cylindrical section are cut diagonally from corner to corner and reoriented along their consistently arched edge. The various panels are connected along their flat edges and ordered to maximize the overall curvature.

The hardware connecting the panels holds the overall form in tension.